What We Believe

We believe that “If it’s not fun it’s not worth doing” so this document and all the supporting documents are written in a fun, story sort of way, our apologies if you don’t get it, it’s just who we are….!!!

Because we care about our people, our customers and our products we have created this document and posted it on the web so that we can all share The Goodtime Pie Co.’s view of the world. We are proud to share OUR HISTORY which spans three generations of bakers.

Without our customers we wouldn’t have a business, so looking after the people who buy our products is built into our DNA. Customer care is central to everything we do. We don’t promise anything we can’t do or provide, but we go all out to deliver on what we have promised, on time, and to meeting or exceeding our customer’s expectations.

We deal straight. We believe our customers want to be treated with honesty, openness and integrity, and that doing this creates the conditions for long-term profitable relationships for both of us.

We also believe our customers expect real value for their money and we want them to feel they are receiving it. The way we run our production is a key part of achieving this.

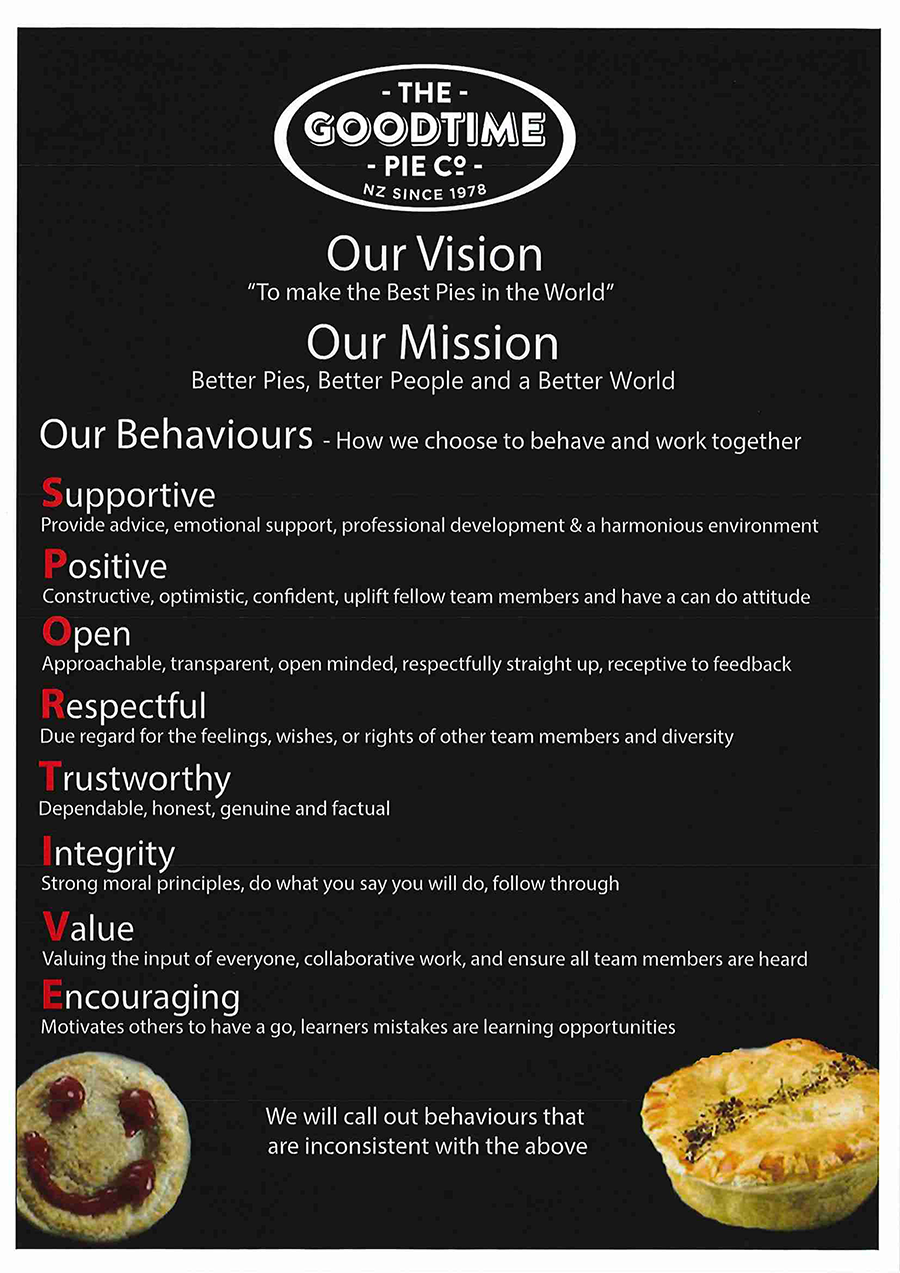

OUR MISSION is to make the “Best Pies in the World”. We want every pie that leaves our place to be the best of the best. Our plant and processes are at the leading edge of bakery innovation and we work relentlessly to stay there. We even make a lot of our own machinery to achieve this.

Along with process and machinery upgrades we are always on the lookout for better ingredients. Our policy is to plough any savings back into the product so enabling further product quality gains. See what we have done so far here

Our commitment to SUSTAINABILITY means we are constantly upgrading our plant, processes, and ingredients to improve product taste, quality, and consistency while reducing resource use and waste. Our primary focus when selecting machinery is to remove the stressful jobs from our process. Upgrades almost always provide significant cost savings from reduced energy use and increased productivity, as well as making better products.

This virtuous cycle feeds on itself, once working, but it won’t start by itself. It has to be powered up and run by engaged, motivated staff willing to accept continuous change and innovation.

We value and look after OUR STAFF as we do our customers. We want The Goodtime Pie Co. to be known as “a great place to work” which is why we have a Staff Representative Committee who are elected, by staff, each year to represent them in all matters concerning them and most importantly to keeping management informed of what’s going on and what they should be doing about it.

We operate a policy of ‘continuous improvement’ with all staff as well as in our processes after all they are the people who make all the processes work.

Most business people will tell you when asked “our staff are our most important asset” well we don’t just pay lip service to that notion we truly believe it and that “happy staff are productive staff” so we do whatever we can to have happy staff. It’s not always possible because after all people are people and some people have difficulty with “happy”. However, we dauntlessly truck on and do what we can. See some of the cool stuff we do with our people.

At The Goodtime Pie Co. we take Health, Safety & Wellbeing very seriously. Our H&S committee meets monthly or where needed as often as is necessary to continuously make or workplace safer. HSW is a key agenda topic in our board meetings where senior managers and directors take it very seriously and take action where there may be a threat to the safety of our people.

FOOD SAFETY is an obvious and very necessary part of any good food business but here at The Goodtime Pie Co. we go to excess, as in a lot of things we do. We first implemented our Food Control Plan (FCP) in 2005 and have maintained and improved on it over the years culminating in a completed revamp of our North Island bakery in 2012/13 which prepared us for a Risk Management Program (RMP) which is like a FCP on steroids. An RMP gives us the ability to export to the world. Then in 2022 we wanted to lift the bar again and researched the most stringent food safety and quality program in the world, and one that had the best global recognition and that was the British Retail Consortium (BRC) standard. We prepared ourselves and went for it and gained certification on our first attempt with a B grade, then an A grade in 2023. Then in 2024 we had un-announced audits and attained an AA+ grade – the highest possible level.

EXPORT has always been a dream for us guys here at The Goodtime Pie Co.. We finally achieved it on August 2015 with our first container of product leaving for Australia on that date.

When we choose a country to export to or are approached by a country who wants to import our pies then we have to go through another process called an OMAR (Overseas Market Access Requirements) this can be onerous but we are a determined pack of guys and girls so we will always have a go.

OUR COMMUNITY is an important part of The Goodtime Pie Co.’s heritage. We are involved where we can be and support where we can with a focus on those in need and helping youth onto good life pathways. To see what we do in this space.

No matter what sort of business you might have it is really important to ensure everyone knows the rules so that we can all row in the same direction, as they say. To this end we have a set of conduct rules which you can see if you click here.

OUR CODE OF CONDUCT. No matter what sort of business you might have it is really important to ensure everyone knows the rules so that we can all row in the same direction, as they say. To this end we have a Dignity and Respect Charter and a set of conduct rules that guide Our Behaviours.